VMware Extends Support For Remote Work With The Latest Saas Innovations On The Horizon Platform

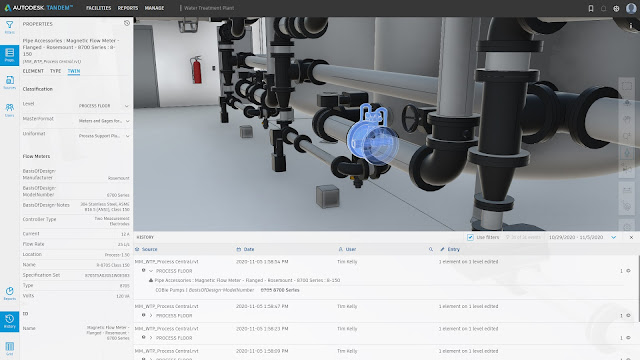

(PC: itbrief.com.au) VMWare Horizon has played a crucial role in how IT supports employees' work, irrespective of how they decide to work. During the initial transition period of remote work in 2020, VMWare's total cloud-deployed Horizon desktops grew by 82%. It has recently announced new capabilities that include SaaS innovations to make it simpler for IT to manage Horizon deployments wherever they may be, on-premise or in the cloud. “Apps are moving to the cloud and employees are accessing them from everywhere, creating a more complex environment for IT to manage,” said Shankar Iyer, senior vice president, and general manager, End-User Computing, VMware. "VMware Horizon is a modern platform built to reduce this complexity, increase management efficiency, and improve employee productivity regardless of whether the desktop and application workloads are on-premises, in the cloud, or a hybrid of both." To know more details, click this link .